Products

Steel mills

Stable quality that excels in every stage of the process

・

Shinko-hamono’s products are used in various stages of steel mills.

By offering long-lasting, high-quality products, we contribute to stable operations.

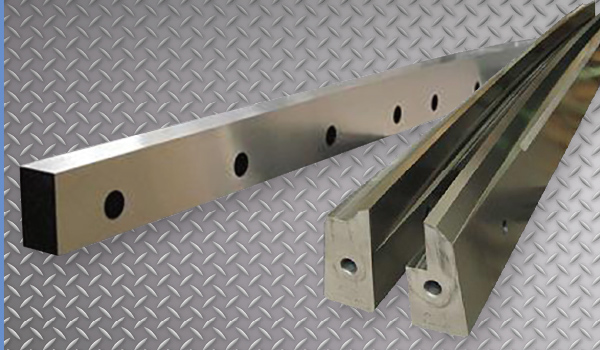

Blades for Slabbing Mills

The slabbing shearing blades are used in slabbing mills and billet mills.These blades crop the front and rear ends of slabs, blooms, and billets, and shear them to the specified lengths.

Since these blades are used in hot conditions, we offer welded blades made from hot work die steel or heat-resistant alloys to meet the demands.

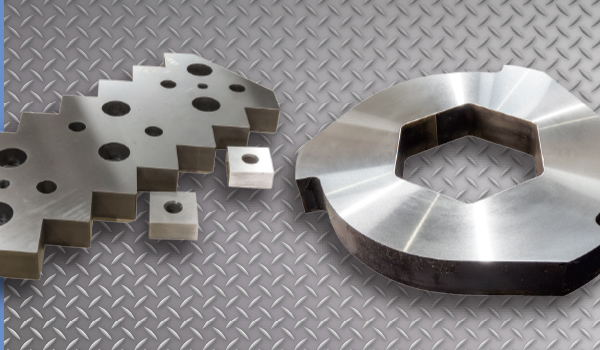

Blades for Heavy Plate Mills

A dividing shear is a blade used in heavy plate mills at steel plants. It trims both sides of steel plates to set the width, then shears them into specified lengths.

It supports plates up to 40mm thick. Since heavy plate shearing involves high loads, the blade material is selected for high toughness steel.

Our company addresses the recent trend of high-tensile heavy plates by using the tough BK series steel.

Blades for Hot Rolling Mills

Crop shears are used in steel mills on hot strip mill lines.In this line, slab material is heated to 1000 to 1150 degrees Celsius in a reheating furnace

and successively rolled by roughing mills. As the front and rear ends deform during this process,

the deformed parts are flying-sheared. The material is then rolled by finishing mills into a well-shaped product and wound into a coil by a coiling machine.

Our company addresses this with WK knives made from hot work die steel, which offers high resistance to thermal softening.

Blades for Cold Rolling and Pickling Plants

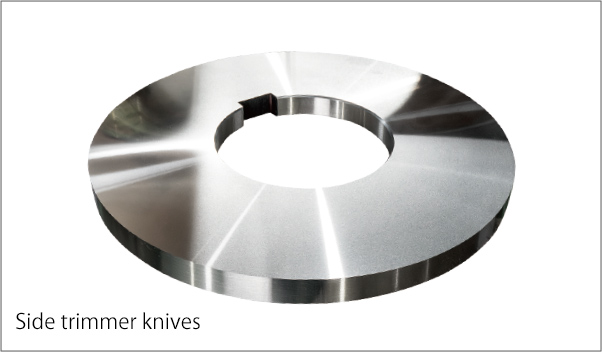

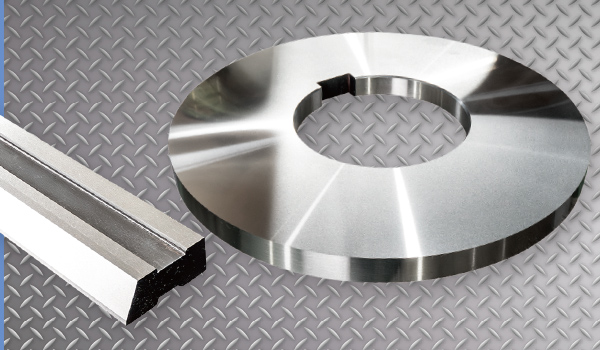

Side trimmer knives are used in side trimming equipment during the steel plate manufacturing process.

After hot rolling and pickling, they continuously trim the edges of the steel plate to achieve the specified width.

In response to the increasing use of high-tensile steel plates, our company enhances durability through the use of BK knives and surface treatment adaptations.

The trimmed edges of the cut steel plates (trim scrap) are processed by waste handling equipment, such as a rotary chopper, which cuts them into strips for disposal.

In response to the increasing use of high-tensile steel plates, our company enhances durability through the use of BK knives and surface treatment adaptations.

When steel plates are welded together, trimming the weld seam with side trimmer knives may cause the knives to chip.

To avoid this, side clipping shears are used to cut the arc-shaped edges of the weld seam, or adjustments are made to the position of the side trimmers.

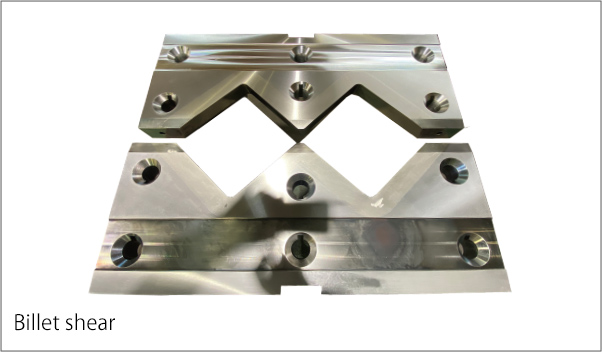

Blades for Wire Rod Mills

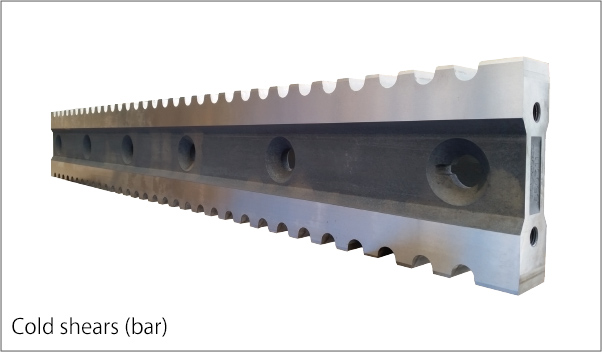

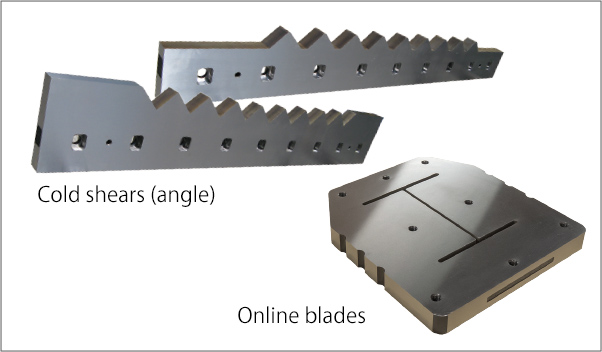

Cold shears are used in continuous bar rolling mills. After the steel billets are heated and the bars and deformed bars are discharged from the finishing mill,

they are cut by flying shears, cooled, and then automatically cut by cold shears.

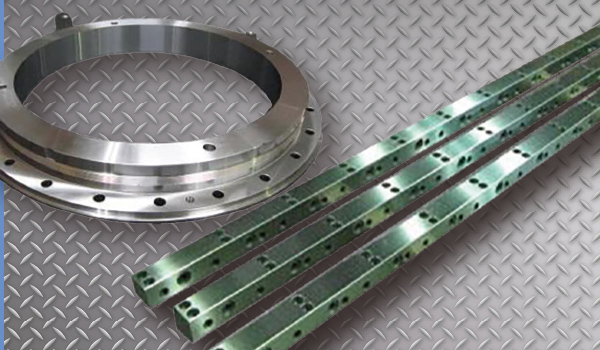

Blades for Structural Steel Mills

In structural steel mills, structural steel used in large buildings, residential construction, bridges, marine structures, roads, and railways is manufactured.

Online blades are used for cutting H-beams to fixed lengths across various sizes.

LINEUP

Secondary processing of steel sheets

Top-class market share in Japan with

exceptional sharpness and wear resistance