Products

Recycling

Contributing to total cost reduction

with minimal chipping and wear

・

Shinko-hamono manufactures blades suitable not only for processing metal scrap

but also for shredding a wide range of waste materials,

including wood chips, waste plastics, tires, electric cables, and printed circuit boards.

Through integrated in-house production, we produce blades that are both tough and resilient.

Due to their strength and low wear rate, Shinko-hamono’s blades extend the blade

replacement cycle, leading to reduced total costs.

Our products are highly regarded by metal scrap dealers and environmental shredder manufacturers.

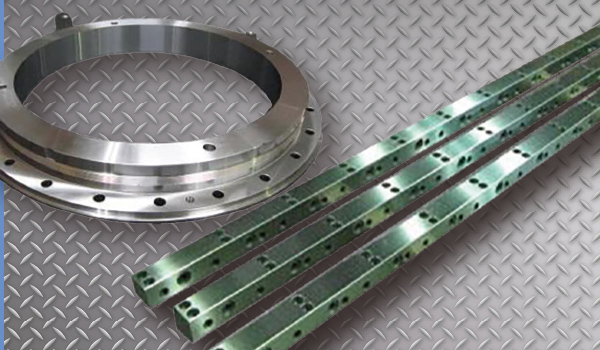

Blades for Metal Shredders

Blades used in large environmental machines for processing metal scrap.

These blades require high toughness and are made from materials that resist chipping and cracking.

We also offer specialized materials for stainless steel processing. Our products are capable of handling specifications such as

heavy load machines and high-speed cutting.

Blades for Construction Machinery

These are blades used in construction machinery for demolition and crushing tasks,

including the dismantling of reinforced concrete structures, steel frames, bridges, roadbeds,

and even ships. We offer a variety of blades that can be attached to different tools to suit these applications.

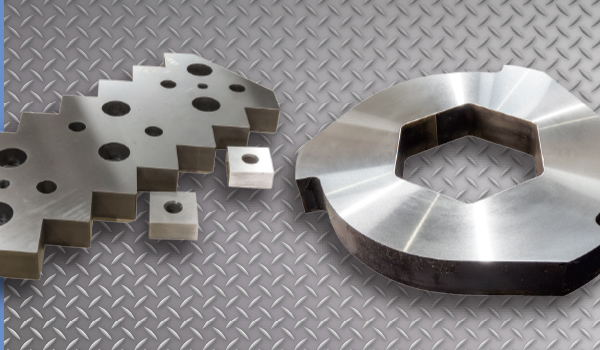

Blades for Twin-Shaft Shredders

Blades used in shredders for recycling waste. They are primarily used for coarse shredding of large materials.

The blade material is selected based on the specifications of the materials to be shredded.

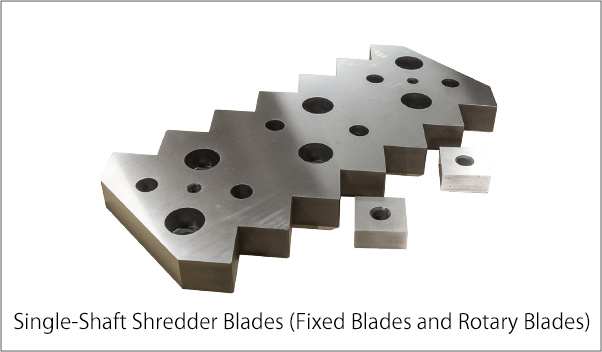

Blades for Single-Shaft Shredders

Blades used in shredders for recycling waste. These blades are utilized in the secondary shredding process to

further reduce the size of materials after coarse shredding. The blade material is selected based on

the specifications of the materials to be shredded.

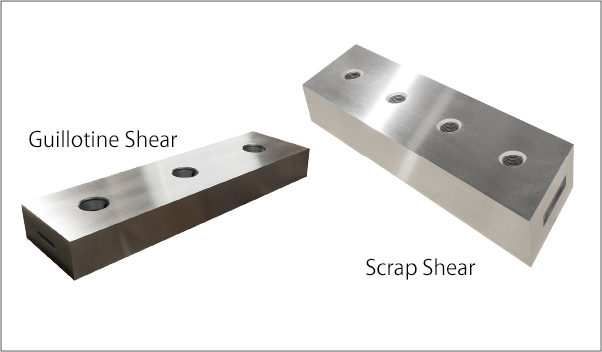

LINEUP

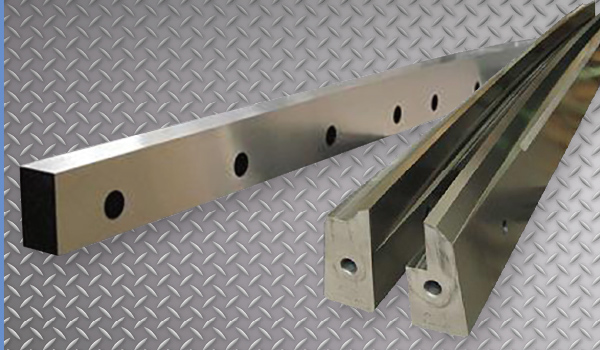

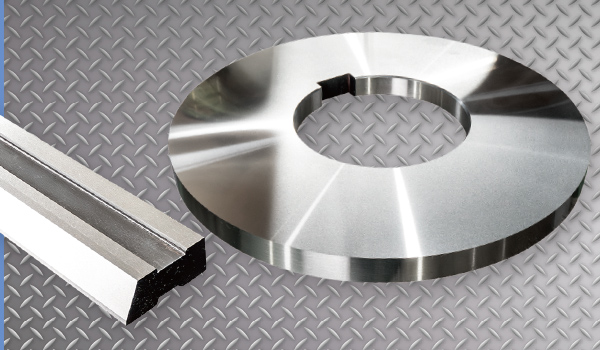

Secondary processing of steel sheets

Top-class market share in Japan with

exceptional sharpness and wear resistance