Products

Secondary processing of steel sheets

Top-class market share in Japan with

exceptional sharpness and wear resistance

・

Shinko-hamono offers original steel grades to meet a wide range of needs.

From ordinary steel plates to high-tensile, stainless steel, electrical steel,

non-ferrous metals, and more, we carefully select blade materials, hardness,

precision, surface roughness, and surface treatments to match the cutting material,

ensuring that we meet your expectations.

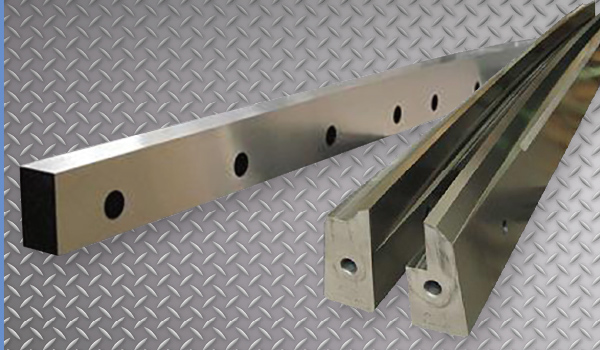

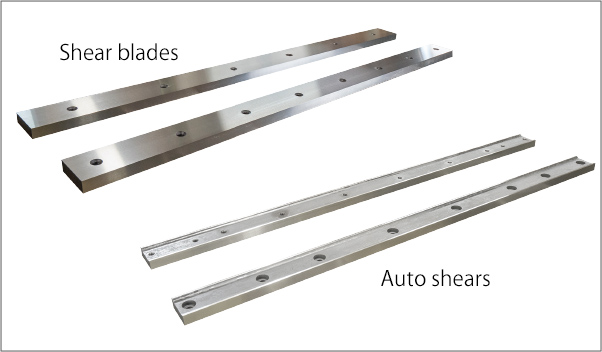

Blades and Components for Shearing Machines

Blades used in shearing machines for sheet metal processing, cutting steel plates to specified sizes.

We offer single-piece shear blades over 6 meters in length and a variety of blade materials to accommodate all types of cutting materials.

Parts used in blade holders for shearing machines and other equipment.

As these parts are affected by the characteristics of the machine and the blades, we provide high-precision components to meet these demands.

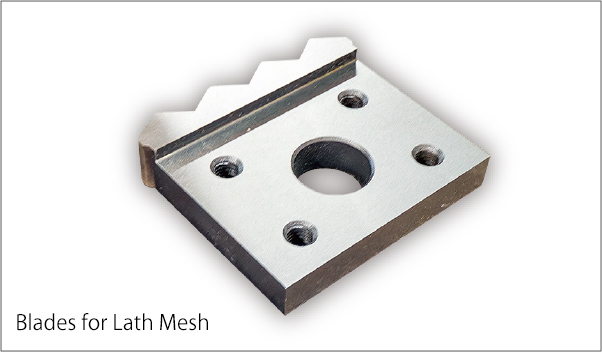

Other Blades for Shearing Machines

Blades used in machines that produce expanded metal (commonly known as lath mesh).

These are used for fences, building construction, and flooring at construction sites.

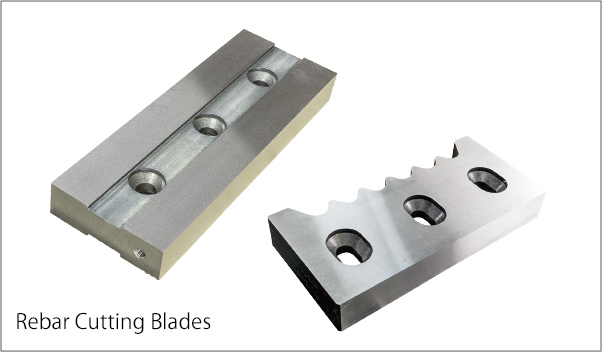

Blades for Rebar Cutting Machines

Blades primarily used in fixed-length cutting machines for D10 to D51 rebars.

In recent years, we have also manufactured cutting blades for high-strength rebars. These blades are compatible with rebar types such as threaded bars (Nashicon).

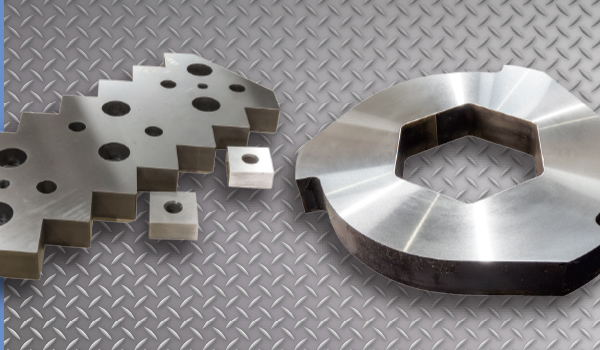

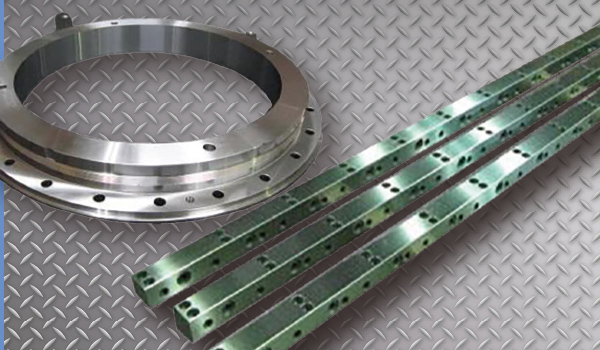

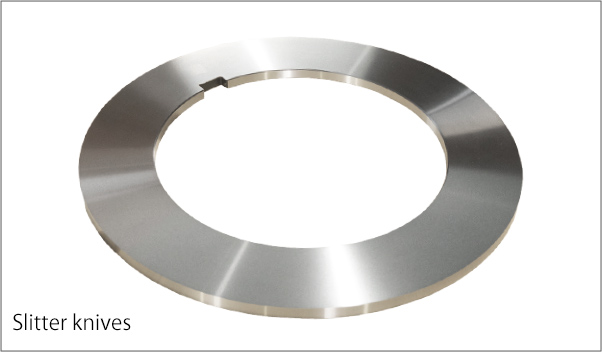

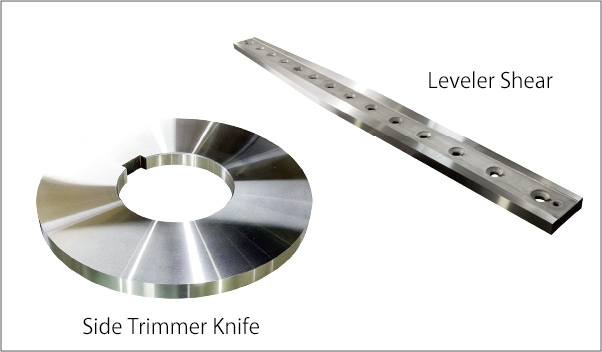

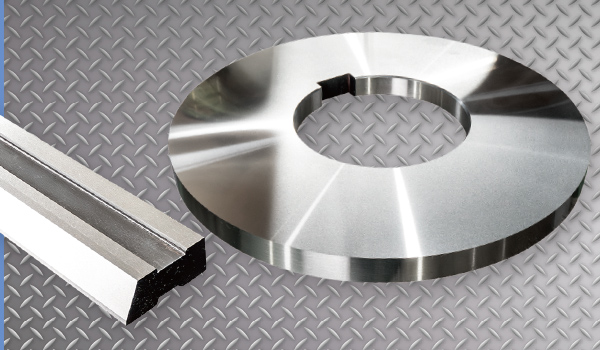

Blades and Components for Slitter Lines

A slitter is a machine that continuously cuts material (coils) to specified dimensions.

Cutters are set at regular intervals using spacers, and rubber rings or fingers prevent the material from bending widthwise during cutting.

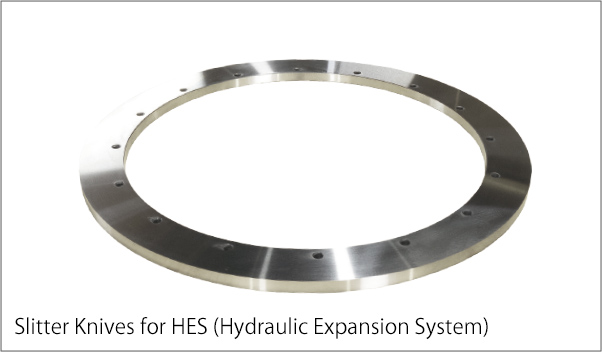

The blades used are called slitter knives. Shinko-hamono’s slitter knives are made from original steel grades, meeting a variety of needs.

From ordinary steel plates to high-tensile steel, stainless steel, electrical steel, and non-ferrous metals, we carefully select the blade’s material,

hardness, precision, surface roughness, and treatments to meet expectations.

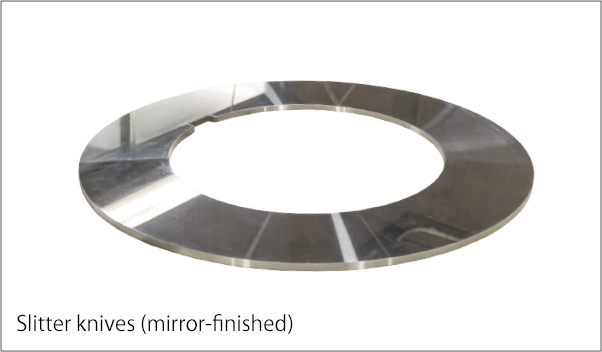

To improve lubrication for slitter knives, we developed a mirror-finished slitter knife that achieves a surface roughness of Rmax 0.3 or less.

A separator disk is a device used in slitter lines to assist with recoiling (rewinding) steel sheets that have been cut to specified widths.

The separator disk holder is the component that supports this disk, ensuring smooth operation during the recoiling process.

Slitter knives typically use spacers, but the HES (Hydraulic Expansion System) type adjusts the coil’s width without spacers by pressing the slitter knives hydraulically.

Slitter spacers used in slitter lines are gauges that determine the specified width of the sheet, so high precision is required.

We coordinate specifications based on the line and the material to be sheared, ensuring the required accuracy is achieved.

Rubber rings used in slitter lines to hold down steel sheets are made from NBR or urethane, with hardness adjusted according to the application.

We also distinguish the rings by color for each diameter as specified. For large slitters, we also produce split-type rings.

In line with knife repair and grinding, we also perform outer diameter grinding of the rubber rings.

Additionally, we manufacture finger-type sheet holders used for processing thin materials.

Blades for Leveler Lines

Leveling processing is a method used by steel manufacturers to straighten steel sheets that have been rolled into coils using rolls and then

cut them through two stages: correction and cutting. The sheets are cut into fixed lengths or other desired sizes.

We offer the most suitable blades for various shearing specifications on small and large leveler lines.

LINEUP

Secondary processing of steel sheets

Top-class market share in Japan with

exceptional sharpness and wear resistance